In today’s society, waste reduction has become a crucial issue in manufacturing. With the increasing demand for goods and the depletion of natural resources, it is more important than ever for manufacturers to find ways to reduce waste and be more environmentally conscious. In this blog post, we will discuss the importance of waste reduction in manufacturing and its benefits for both the environment and the economy.

One of the main reasons why waste reduction is important in manufacturing is because of its impact on the environment. Manufacturing processes produce a significant amount of waste, including hazardous materials and emissions that can harm the environment. By reducing waste, manufacturers can minimize their environmental footprint and help preserve natural resources for future generations. In addition, reducing waste can also help reduce pollution and combat climate change, as many manufacturing processes release greenhouse gases into the atmosphere.

Another reason why waste reduction is crucial in manufacturing is because it can lead to cost savings for companies. Waste disposal and management can be expensive, both in terms of financial costs and resources. By reducing waste, manufacturers can lower their operating costs and improve their overall profitability. In addition, waste reduction can also lead to increased efficiency and productivity, as companies can focus on producing high-quality products without the burden of excess waste.

Furthermore, waste reduction can also help improve the overall reputation of a company. In today’s society, consumers are becoming increasingly aware of environmental issues and are more likely to support companies that are environmentally responsible. By promoting waste reduction initiatives, manufacturers can attract environmentally conscious consumers and improve their brand image. In addition, waste reduction can also help companies comply with environmental regulations and avoid potential fines and penalties.

There are many ways in which manufacturers can reduce waste in their operations. One of the most common methods is through recycling and reusing materials. By implementing a recycling program, manufacturers can divert waste from landfills and reduce their environmental impact. In addition, reusing materials can help companies save money on raw materials and reduce their overall production costs.

Another way to reduce waste in manufacturing is through process optimization. By analyzing and improving manufacturing processes, companies can identify areas where waste can be minimized or eliminated. For example, companies can optimize their production schedules to reduce excess inventory or implement lean manufacturing principles to eliminate waste in their operations. By continuously monitoring and improving their processes, manufacturers can achieve significant reductions in waste and improve their overall efficiency.

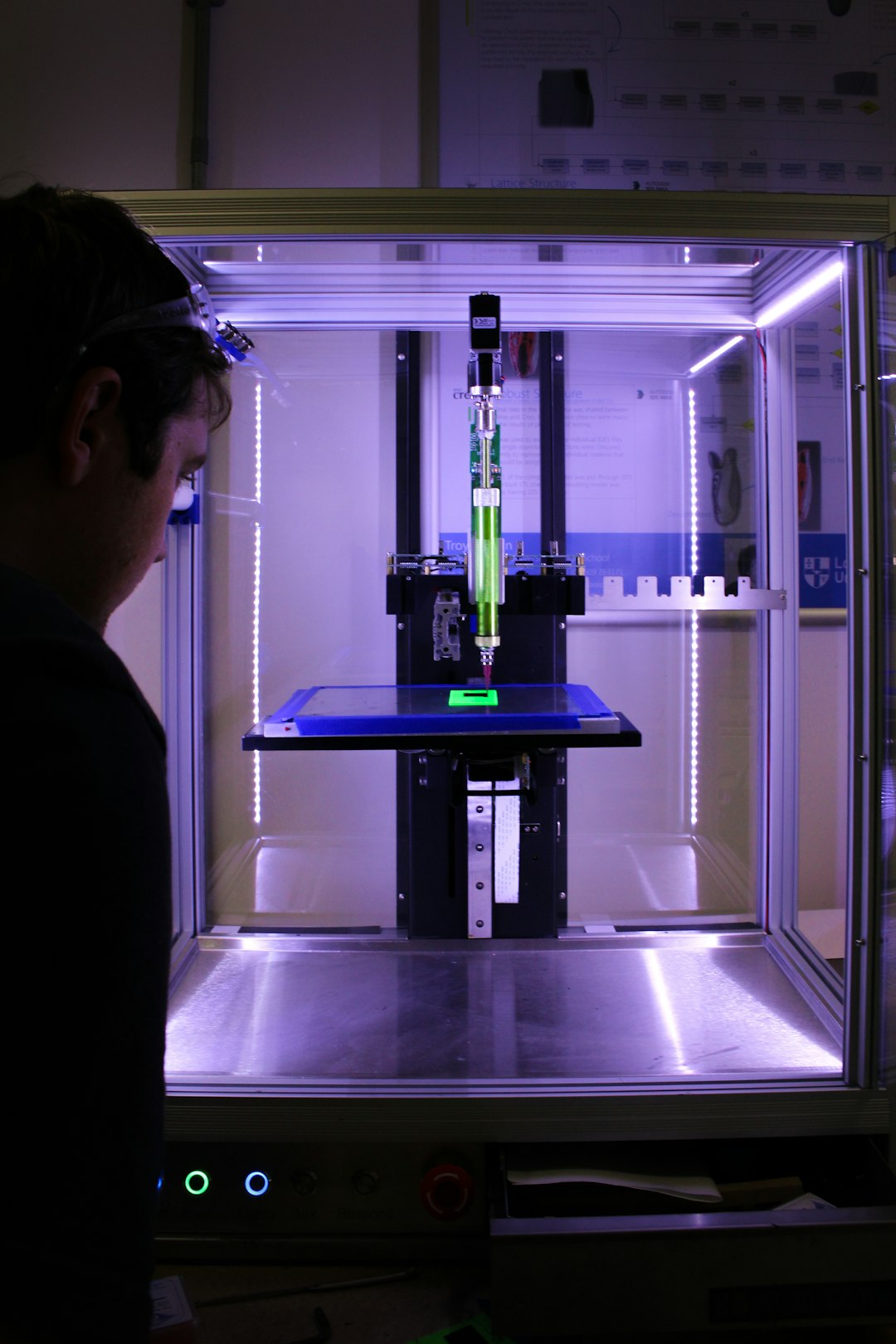

Additionally, manufacturers can also reduce waste by investing in new technologies and equipment. Automated systems and advanced machinery can help companies streamline their production processes and minimize waste. For example, robotic systems can improve precision and reduce errors, leading to fewer defects and less waste. By investing in modern technologies, manufacturers can not only improve their environmental performance but also enhance their competitiveness in the market.

In conclusion, waste reduction is a critical issue in manufacturing that can have significant benefits for the environment, the economy, and society as a whole. By implementing waste reduction initiatives, manufacturers can minimize their environmental impact, reduce operating costs, improve their brand image, and increase their overall efficiency. As consumers become more environmentally conscious, waste reduction will become increasingly important for companies to remain competitive in the market. Therefore, manufacturers must prioritize waste reduction in their operations and work towards creating a more sustainable future for all.